Tipps & Tricks

Tips & Tricks

Technical Note 1: Rechargeable Battery Maintenance

- General Information

- Charging Deeply Discharged Batteries

- Solving the Problem of a Reduced Operating Spanr

- 3.1 Checking the Battery Capacity

- 3.2 Checking the Integrated Charging System

- 3.3 Checking the Data Logger

- Facts About Rechargeable Batteries

- Recommended Equipment

The data logger is operated by 2 NiMH rechargeable batteries of the AA (Mignon) size. The operating span is influenced by the quality and in particular by the state of charge of the batteries used. When fully functional and freshly charged batteries with an indicated capacity of 2000mAh are applied, the operating span of the MOUSE-E-MOTION Universal Data Logger is up to 150 days (depending on the configuration of the logger). Note that the effective capacity of the utilized batteries is critical for that. The effective capacity of rechargeable batteries decreases inevitably over time, even with constantly thourough handling. Rechargeable batteries with an indicated capacity of 2000mAH, for example, will have an effective capacity of only about 1500mAH after permanent usage for two years. So, regardless of the quality of maintenance, the effective capacity is just about 75% of the original value. With insufficient care the effective capacity can even go far below 50% of the indicated capacity. Correspondingly, the operating span of the MOUSE-E-MOTION Universal Data Logger is significantly reduced when such batteries are used.

The best way to preserve the reliable functioning of rechargeable batteries is to use a separate, so-called “intelligent” battery charger, such as the ALC 2000 charger from Conrad Electronic (www.conrad.de). This charging device charges up to 8 batteries of type AA simultaneously and safely. The charging time is 3 to 4 hours. The charger also allows for testing your batteries after a longer period of permanent usage or when a reduced battery capacity is suspected. To reliably achieve optimal performance of your rechargeable batteries, please follow the subsequently listed instructions and recommendations:

- Always power off a data logger after running, otherwise the batteries might become deeply discharged.

- Avoid running a data logger until the batteries are completely discharged. Exchange the batteries in time before starting a new logging task.

- Have a second set of charged batteries for each operating data logger at hand so you will be able to run the devices without unnecessary interruption.

- Handle the rechargeable batteries thoroughly and check their effective capacity regularly.

- Only use rechargeable batteries of the same type as the ones originally provided with the data logger.

- Never use rechargeable batteries of diverse manufacturers, different age or mismatching capacity in the same data logger.

- Always charge your rechargeable batteries in a separate charger, regardless of their actual state of charge.

- Do not use incompatible rechargeable batteries with the integrated charging system of the MOUSE-E-MOTION Universal Data Logger as this may result in a radically reduced operating span (such rechargeable batteries are not charged correctly).

2. Charging Deeply Discharged Batteries

Batteries that have been completely discharged during data logger operation and then remain within the device might become deeply discharged. Such batteries might not be charged without special treatment, neither with the data logger’s charging system nor in a separate charger. This is caused by the circumstance that the batteries have been discharged down to a cell voltage of nearly 0V. In this case, the charging system cannot recognize the batteries. Moreover, even if deeply discharged batteries have been succesfully regenerated, they might not regain their full original capacity.

Using the ALC 2000 charger deeply discharged or defective batteries can easily be identified. For this purpose, insert the battery into a charging compartment. The battery should be recognized and, after a short period, charging should be initiated. This is indicated by the respective green LED indicator. If the LED indicator of a charging compartment is not illuminated after a period of 1 minute, the respective battery is not recognized by the charging system, presumably because of it is deeply discharged. Such batteries have to be regenerated prior to being able to charge them (see 2.1). When batteries are being charged, always check if the green LED indicator is illuminated 2 minutes after the batteries have been placed into the charger.

2.1 Regenerating Deeply Discharged Batteries

Usually, applying a short power pulse of 500 to 1,000mA for 5 to 10 seconds to deeply discharged batteries helps to regenerate them. In most cases the batteries are recognized again by the charger afterwards and then properly charged.

The ALC 2000 charger allows for the easy regeneration of deeply discharged batteries. Insert a battery that is discharged (but not deeply discharged!) into one of the charging compartments. After a few seconds, charging should commence, signalled by the respective green LED indicator. Now attach the deeply discharged battery in correct polarity to the upper contacts of that compartment where the previously inserted battery is charged. The deeply discharged battery is now supplied with power in parallel to the other battery. Afterwards, this battery can be placed into another empty compartment of the charger. It should be recognized by the charger now and properly being charged.

You can also use an exernal power supply to apply a power pulse to the deeply discharged battery (500 to 1,000mA, 2V maximum voltage).

2.2 Testing Regenerated Batteries

Deeply discharged batteries that have been succesfully regenerated sometimes do not regain their full original capacity. Using the ALC 2000 charger you can test the present capacity of a battery (“Test” function, refer to the ALC 2000 operating instructions). The battery is being charged, discharged and then recharged. The present cell voltage and the charging/discharging current is monitored on the display. The ALC 2000 charger also supports optimizing batteries (Regenerating, refer to the ALC 2000 operating instructions). Often it is possible to completely regenerate the original capacity of a battery.

3. Solving the Problem of a Reduced Operating Span

A reduced operating span of the MOUSE-E-MOTION Universal Data Logger can have one of the following causes:

- the batteries are defective

- the batteries are not charged properly by the integrated charging system

- the data logger has a malfunction

3.1 Checking the Battery Capacity

Using the ALC 2000 charger, check the capacity of a battery freshly charged by the integrated charging system of a data logger. The determined effective capacity should not be less than 80% of the value (mAH) indicated on the battery, otherwise this battery should be discarded. If a battery does not reach its indicated capacity any more, it might be recovered with the “Regenerating” function of the ALC 2000 charger (refer to the ALC 2000 operating instructions).

3.2 Checking the Integrated Charging System

Using the supplied power adaptor, charge two functional and discharged (but not deeply discharged) batteries of the recommended type with the integrated charging system of the MOUSE-E-MOTION Universal Data Logger. After charging has been completed, check the battery capacity with the ALC 2000 charger. If the measured capacity is considerably smaller than the indicated capacity (mAH) of the battery, there may be a malfunction of the charging electronics of the data logger. Return the data logger for an extensive investigation. (If this is observed when batteries different from the recommended types are used, these batteries are probably not compatible with the integrated charging system.)

To check for a malfunction in the data logger’s electronics connect the device to an external power supply and determine the power consumption with an appropriate measuring instrument. The instrument should be capable to compute an average value (AVG). Remove the batteries from the battery compartment of the data logger. Connect the contacts in the battery compartment with an external power supply ensuring the correct polarity. Apply a voltage of 2.2 to 2.7V and a current limitation of 150 to 500mA. Warning: A voltage higher than 4V will cause irreparable damage to the device ! The MOUSE-E-MOTION Universal Data logger has an automatic fuse, so it is not possible to cause damage to the device if the polarity is swapped. The fuse will re-enable itself after a short time if triggered. Determine the current consumption of the data logger. The following table shows the values within the tolerance range that should be observed in average mode (AVG):

| Data logger is powered off: | |||

|

min. 0,01 mA

|

typ. 0,02 mA

|

max. 0,1 mA

|

peak Value (non-AVG): 0,1 mA

|

| Data logger is in standby mode, PC-interface cable not connected to the device: | |||

|

min. 2,0 mA

|

typ. 3,5 mA

|

max. 7,0 mA

|

peak Value (non-AVG): 25 mA

|

| Data logger in logging mode, PC-interface cable not connected to the device: | |||

|

min. 0,6 mA

|

typ. 1,2 mA

|

max. 2,0 mA

|

peak Value (non-AVG): 25 mA

|

If higher values are detected the data logger might have a malfunction. Please return the device for inspection and repair.

4. Facts About Rechargeable Batteries

- It is not necessary to completely discharge partly discharged batteries. It even might reduce their life span. (The so-called “memory effect” is practically not detectable with NiMH rechargeable batteries.)

- Using the ALC 2000 charger to charge rechargeable batteries will limit the loss of capacity caused by the normal ageing process to less than 35% over a period of 2 years.

- Frequent deep discharge of rechargeable batteries will result in an acute and enduring loss of capacity.

- Self-discharge of NiMH rechargeable batteries is about 2% to 5% per month. If an overall loss of capacity of 10% is acceptable, charged batteries may be stored up to 3 months before they are used.

5.1 Rechargeable Batteries

Typ NiMH 2000 or NiMH 2100 from Panasonic.

These rechargeable batteries function very reliable, even when they are regenerated after having been deeply discharged.

ALC 2000 Expert from Conrad Electronic (www.conrad.de)

Item-No. 25 03 85-50, ~ 149,00 € (w/o VAT)

Download ‘Technical Note 1: Rechargeable Battery Maintenance’ as PDF document.

Speeding up the log data download

For compatibility reasons, the preset transfer rate of the MOUSE-E-MOTION Universal Data Logger is 9,600 bps (bits per second = baud). It is recommended to set the transfer rate to the highest possible value (115,200 baud) before the data logger is used for the first time. This reduces the time needed for a log data download significantly. (For those extremely rare cases that communication problems should occur after having done this, refer to the ‘Troubleshooting‘ page.)

Automatically determine the baud rate used by a data logger

In the case that the baud rate a particular data logger is set to is unknown, it can be determined automatically with the MOUSE-E-MOTION Excel add-in from version 2.3 on. To enable this function, select the check box Auto-determine under General serial port settings on the Communication tab of the Options dialog box. Now, the data logger can be detected using the Detect command of the MOUSE-E-MOTION toolbar, or the MOUSE-E-MOTION menu, respectively. Note that the detection procedure might need significantly more time, if Auto-determine is enabled. For this reason, it is recommended to activate this function only if necessary and to disable it afterwards.

Application Note: Motion Sensors

- Selecting the Appropriate Motion Sensor

- Connecting an External Motion Sensor to the Data Logger

- Ensuring Consistent Motion Detection During Activity Monitoring

1. Selecting the Appropriate Motion Sensor

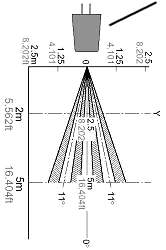

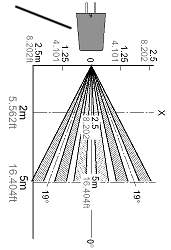

The motion sensors differ in their detection range and the geometry of the area they are covering:

The motion sensor of the Spot type has a rectangular detection base whereas the motion sensor of the Slight Motion type has a circular detection base and a wide-angle detection range, potentially covering a larger area (see figures below).

1.1 Spot Type Motion Sensor (yellow mark)

| Built-In: | External: | ||

|

|

|

|

Detection range

| Front view | Side view | COVERED BASE AREA |

| Motion sensor(Infrared sensor) | ||

|

|

|

Orientation of the sensor and the yellow colour mark on the back:

|

|

|

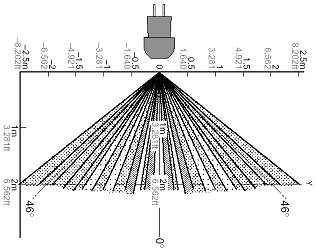

1.2 Slight Motion Type Motion Sensor (green mark)

| Built-In: | External: | ||

|

|

|

|

Detection range:

| SIDE VIEW | COVERED BASE AREA |

|

|

More information about the infrared-based motion sensors can be found on the website of the manufacturer NAiS: Website NAiS

Note

Polycarbonate, acrylic or similar material usually is not permeable to infrared radiation. Thus, it is not possible to detect motion through walls of such material. The motion sensors should always have direct access to the object being monitored.

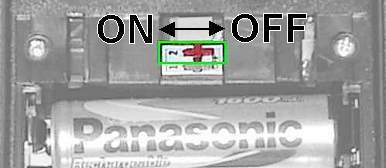

2. Connecting an External Motion Sensor to the Data Logger

An external motion sensor is connected to the 9-pin connector at the right side of the data logger:

To exclusively use an external motion sensor, the internal motion sensor has to be disabled. For this purpose, move the red switch (accessible after opening the battery compartment, see figure below) to the OFF position:

Keep in mind that it is necessary to move it back to the ON position and to disconnect the external motion sensor, if you want to exclusively use the internal motion sensor again! If an external motion sensor is connected and the internal motion sensor is not switched off, the signals of both sensors are mixed and it is not possible to differentiate which sensor contributed to what extent to the resulting value of a recording interval.

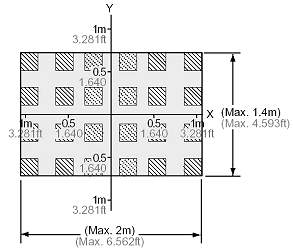

3. Ensuring Consistent Motion Detection During Activity Monitoring

To ensure reliable detection of the entire motion within the experiment area, verify that motion is detected throughout the whole space of the experiment box and that motion of persons or other animals or objects outside of it is not detected.

When the Slight Motion type motion sensor is used, it is very unlikely that any region within the experiment area is uncovered, however, we suggest to test it despite of that. When the Spot type motion sensor is used, depending of its position above the ground of the chamber, it is possible that not the whole area might be covered.

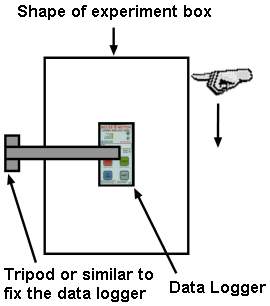

A method to test the proper detection inside an experiment box might be the following:

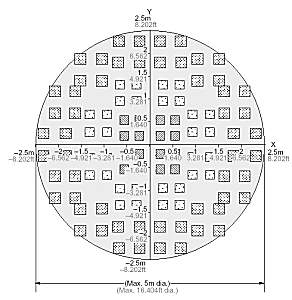

| View from above: | |

|

Draw the shape of the bottom of the experiment box on paper. Fix the motion sensor/data logger exactly in that height and position above the paper that it would have if it were placed on the cover of the box. Now slowly move the tip of a finger pointing from the outside of the rectangle to its inside in a height of 2 to 3 cm above the line. On the front of the data logger, you should see a permanent flashing of the triangle-LED with the tip to the top. If no signal is visible, motion cannot be detected in the respective region the finger moves. Accordingly, the motion of an animal moving in that part of the experiment box would not be detected with certainty. |

|

To ensure that no motion outside an experiment box is detected, position the motion sensor/data logger over the empty box (no animal inside) as you would do it during the real experiment. Now, move your hand around the box and watch the LED-indication on the front of the data logger. No signal should occur. If the triangle-LED with the tip to the top flashes, additional shielding of the box is necessary to prevent false detections.

Download ‘Application Note 1: Motion Sensors’ as PDF document.

Do you have a tip for the MOUSE-E-MOTION data logger? Do you know a trick?

Please write to: Kontakt